Savings potential with .analytics

Identification of savings potential through analyses

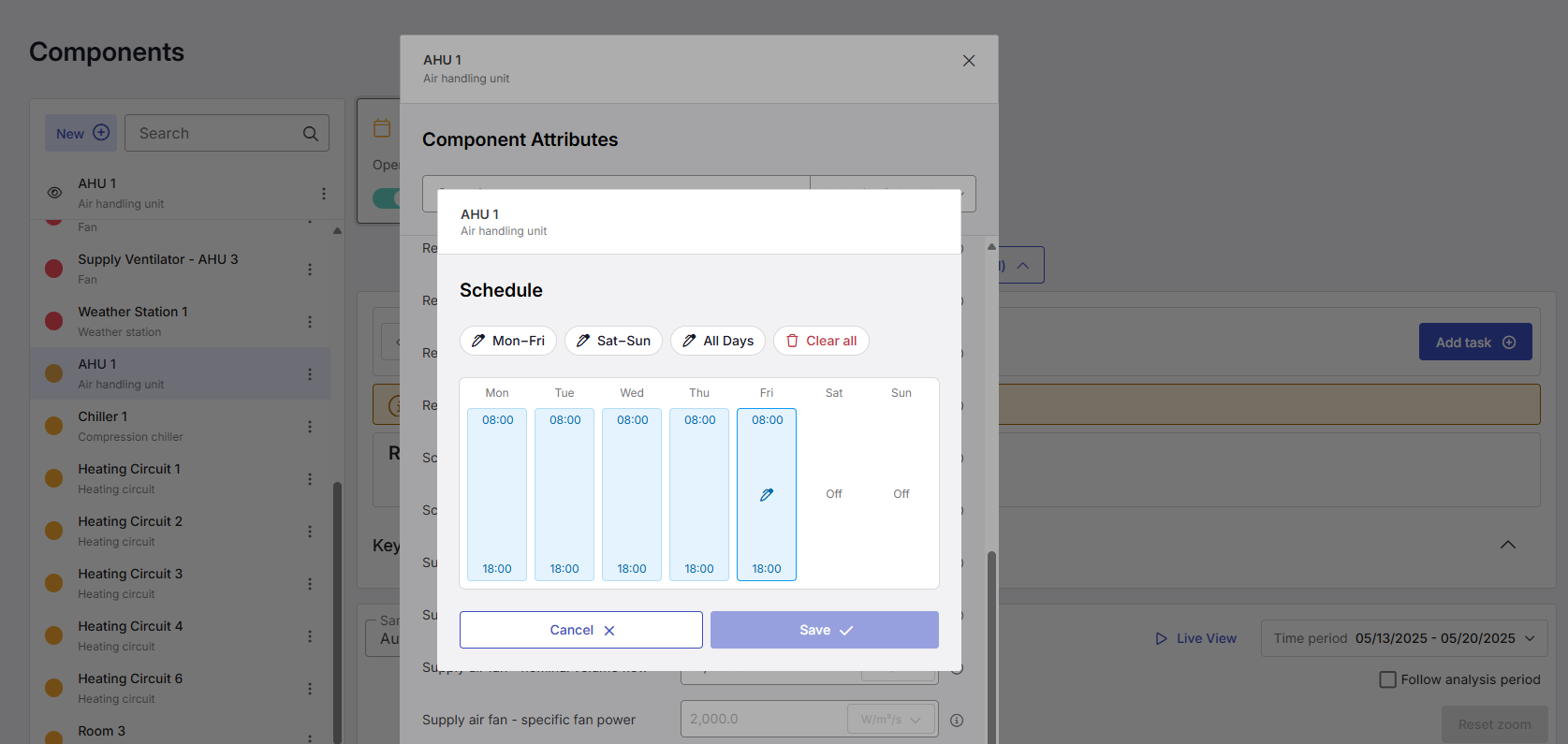

Schedule

This section focuses on using the "Schedule" analysis for the component Air handling unit (AHU).

Functionality

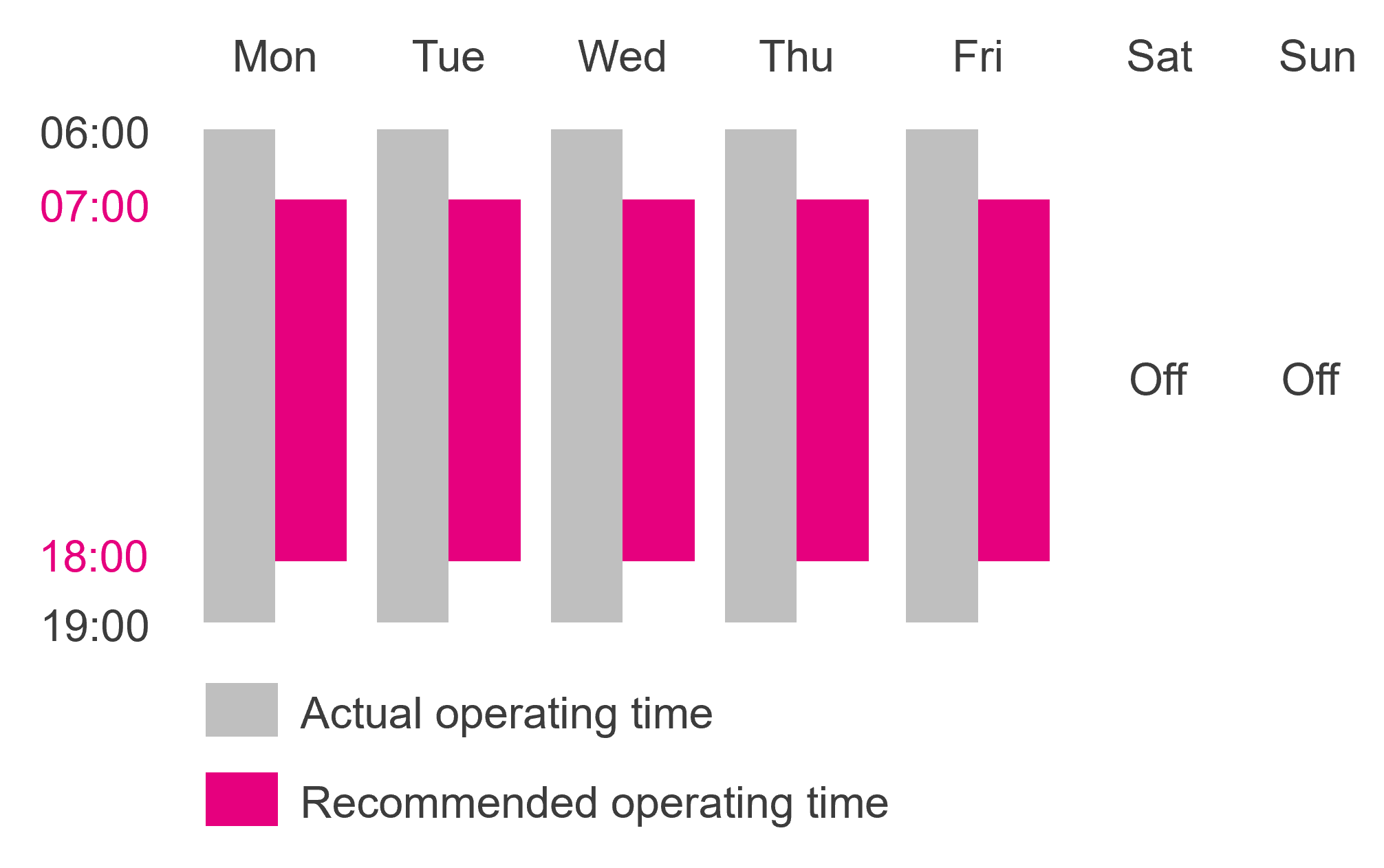

The “Schedule” analysis compares the actual and recommended schedule and determines the operating time that can be reduced.

Added value

- Identification of the reducible operating time

- Calculation of savings potential by reducing the operating time

- Extrapolation of the savings potential to a calendar year

Prerequisites

- Actual schedule

The operation is recognised automatically based on the component's mapped data points. The prerequisites for this are usually met once the component has been set up. - Recommended schedule

The component's recommended schedule must be defined. To achieve this, set the "schedule" attribute by selecting the operating times for each day of the week. - Information on the component's power

In order to calculate the savings potential, information on the power or volume flow of the supply and/or extract air fan must be available. At least one of the following must be defined:- Nominal power - fan (attribute)

- Nominal volume flow - fan (attribute)

- Volume flow - fan (pin)

- Adjustment of the attributes (optional)

Adjusting the attributes makes the analysis result and the calculated savings potential more accurate. Typically, at least the following attributes should be checked:- Energy prices: electricity, heat, cold

- Heat recovery system active during heating/cooling

Result

The following key figures are useful for interpreting the results of the analysis:

| Key figure | Example |

|---|---|

| week schedule.recommended | Mon-Fri: 06:00-19:00 |

| Supply fan.week schedule.actual* | Mon-Fri: 07:00-18:00 |

| Supply fan.operating time.reducible* | 10 h |

| total yearly savings potential.energy | 10000 kWh |

| total yearly savings potential.financial | 2000 € |

| total yearly savings potential.CO2 emissions | 4000 kg |

* similar for the exhaust fan